Table of Contents

Introduction

Master Microgreens Harvesting Storage & Tips (2025) transforms home growers from beginners into skilled producers of restaurant-quality greens. This comprehensive guide covers everything from perfect harvest timing to commercial-level growing techniques that maximize both quality and yield.

Understanding Master Microgreens Harvesting Storage & Tips (2025) determines the difference between mediocre results and exceptional homegrown produce. The advanced techniques covered here represent years of commercial growing experience adapted for home gardeners seeking professional-level results.

Learning to Master Microgreens Harvesting Storage & Tips (2025) requires precise timing and proper storage methods that preserve peak nutrition and freshness. These proven strategies ensure your harvest maintains its vibrant flavor and crisp texture for weeks after cutting.

When you successfully Master Microgreens Harvesting Storage & Tips (2025), you’ll discover how professional growers achieve consistent quality and extended shelf life. The storage secrets revealed in this guide can transform your microgreens from a short-lived harvest into a long-lasting supply of fresh nutrition.

By implementing these Master Microgreens Harvesting Storage & Tips (2025) techniques, home growers can achieve results that rival commercial operations while maintaining the superior quality that only comes from careful, hands-on cultivation.

When and How to Harvest Microgreens

Harvesting techniques determine both yield and quality of the final product. Timing represents the most critical factor in microgreen production. Harvest too early, and yields suffer. Wait too long, and flavors become bitter while nutritional content declines.

Identifying harvest time requires understanding each variety’s growth pattern. Most microgreens reach optimal maturity seven to twenty-one days after planting. Cotyledons should be fully expanded, and the first true leaves may be emerging or just visible.

Visual indicators include vibrant colors, sturdy stems, and fully opened seed leaves. Plants should appear healthy and vigorous without signs of yellowing or wilting. The growing medium should still be moist but not waterlogged.

Cutting techniques maximize yield while maintaining quality. Use clean, sharp scissors or a knife to cut stems just above the soil line. Avoid pulling plants, which can disturb neighboring microgreens and introduce soil into the harvest.

Tools needed for harvesting include sharp scissors, clean containers for collecting cut greens, and paper towels for initial cleaning. Sanitized tools prevent contamination that can reduce shelf life and food safety.

Post-harvest handling begins immediately after cutting. Gently shake harvested microgreens to remove any growing medium particles. Rinse briefly in cool water if necessary, but avoid overwashing, which can damage delicate leaves.

Storage methods extend shelf life and maintain quality. Fresh microgreens store best in refrigerated conditions between thirty-five and forty degrees Fahrenheit. Use perforated bags or containers that allow air circulation while preventing moisture loss.

Proper storage techniques can maintain microgreen quality for five to ten days. Place paper towels in storage containers to absorb excess moisture. Replace damp towels as needed to prevent mold development during storage.

Harvest timing affects both nutritional content and flavor intensity. Peak nutrition typically occurs when cotyledons are fully expanded but before true leaves develop. Some growers prefer slightly more mature microgreens for stronger flavors.

Common Problems and How to Solve Them

Mold growth represents the most frequent challenge in microgreen production. Prevention starts with proper sanitation and environmental control. Clean containers, sterile growing medium, and appropriate air circulation significantly reduce mold risks.

Treatment options for existing mold include improving air circulation, reducing watering frequency, and removing affected areas. Severely contaminated trays may need complete disposal to prevent spreading to healthy crops. Hydrogen peroxide solutions can help control minor mold outbreaks.

Leggy growth results from insufficient lighting or overcrowding. Weak seedlings with long, thin stems lack the sturdy structure needed for quality microgreens. Increasing light intensity and duration usually corrects this problem for future plantings.

Poor germination can result from old seeds, incorrect moisture levels, or inappropriate temperatures. Seed viability decreases over time, so purchase fresh seeds from reputable suppliers. Germination testing helps identify problem seed lots before large plantings.

Troubleshooting germination issues involves checking moisture levels, temperature, and seed quality systematically. Seeds need consistent moisture but not waterlogged conditions. Temperature fluctuations can significantly impact germination rates and timing.

Pest management in indoor growing environments typically involves preventing infestations rather than treating established problems. Fungus gnats can develop in overly moist conditions. Yellow sticky traps help monitor and control adult flies.

Yellowing microgreens indicate several possible issues including nutrient deficiency, overwatering, or poor air circulation. Root rot from waterlogged soil causes similar symptoms. Improving drainage and reducing watering frequency often resolves these problems.

Wilting problems can result from both underwatering and overwatering. Check soil moisture levels and adjust watering accordingly. Consistent moisture prevents stress that leads to poor quality microgreens.

Disease prevention strategies include using sterile growing media, sanitizing tools and containers, maintaining proper environmental conditions, and providing adequate plant spacing. Organic fungicides can help prevent damping-off diseases in susceptible crops.

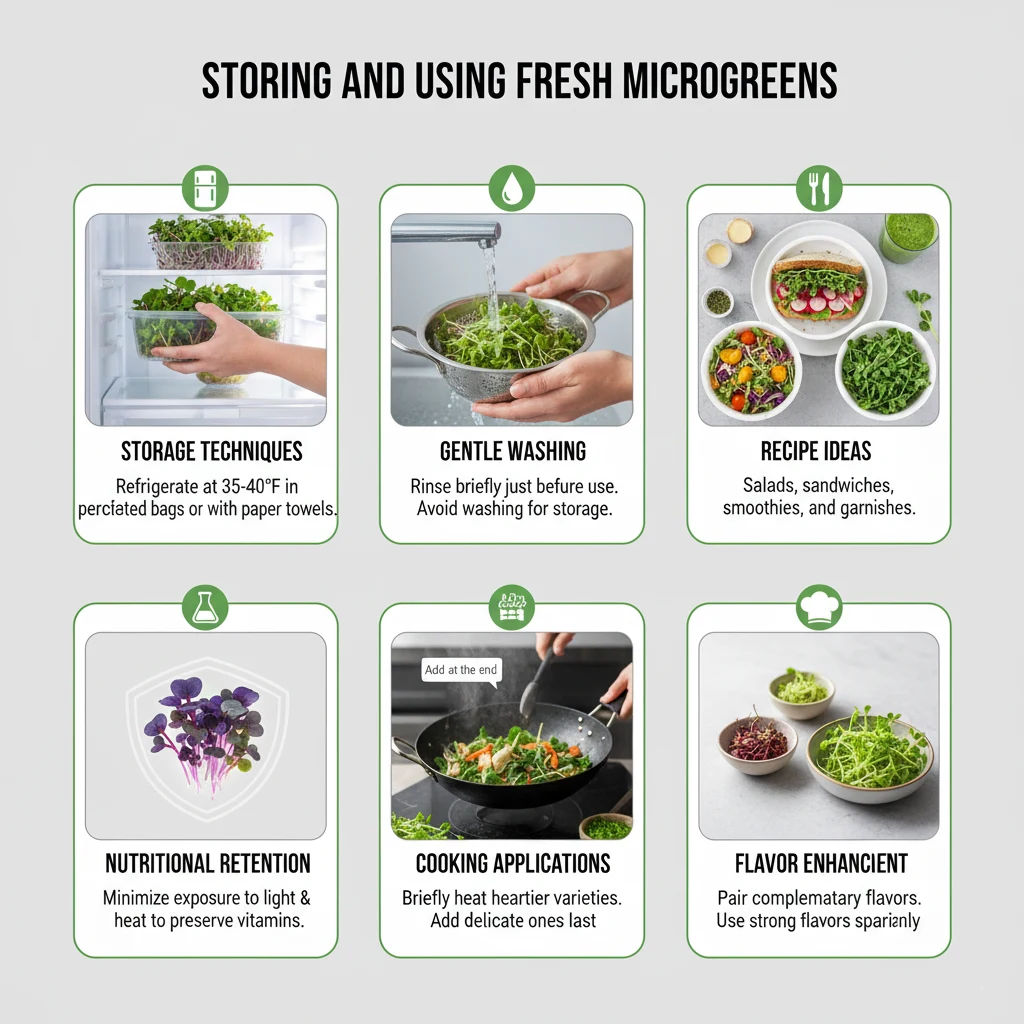

Storing and Using Fresh Microgreens

Storage techniques significantly impact the shelf life and quality of harvested microgreens. Refrigeration at temperatures between thirty-five and forty degrees Fahrenheit slows respiration and maintains freshness. Higher temperatures accelerate deterioration and reduce nutritional value.

Container selection affects storage success. Perforated plastic bags allow air circulation while preventing excessive moisture loss. Airtight containers can work if they include paper towels to absorb excess moisture and prevent condensation buildup.

Washing methods should be gentle to avoid damaging delicate leaves and stems. Rinse microgreens briefly in cool water just before use rather than immediately after harvest. Excessive washing can introduce moisture that promotes decay during storage.

Preparation techniques vary by intended use. Raw applications like salads and garnishes require minimal preparation beyond gentle washing. Cooking applications may benefit from slightly longer stems that won’t disappear during brief heating.

Recipe ideas showcase the versatility of homegrown microgreens. Sandwich applications benefit from peppery varieties like radish and arugula. Salad enhancement works well with mild varieties like pea shoots and sunflower greens.

Smoothie additions provide concentrated nutrition without overwhelming flavors. Start with small amounts of mild varieties and adjust quantities based on taste preferences. Green smoothies can incorporate larger quantities of neutral-tasting microgreens.

Nutritional retention depends on proper handling and storage. Vitamin content degrades rapidly when microgreens are exposed to light, heat, and air. Minimizing exposure to these factors maintains nutritional value longer.

Cooking applications should involve brief heating to preserve both nutrition and texture. Stir-frying works well with heartier varieties like pea shoots and sunflower microgreens. Add delicate varieties at the end of cooking to prevent wilting.

Flavor enhancement techniques include pairing complementary varieties and using appropriate quantities. Strong-flavored microgreens like mustard and radish work well in small quantities, while mild varieties can be used more liberally.

| Storage Method | Shelf Life | Best For | Key Considerations |

|---|---|---|---|

| Plastic bags (perforated) | 5-7 days | Most varieties | Prevents moisture buildup |

| Airtight containers | 7-10 days | Delicate varieties | Include moisture absorber |

| Paper towel wrapping | 3-5 days | Short-term storage | Change towels regularly |

| Hydroponic storage | 10-14 days | Living microgreens | Requires specialized setup |

Cost Analysis: Growing vs. Buying Microgreens

Initial setup costs for microgreen production vary significantly based on chosen equipment and growing methods. Budget-friendly approaches using recycled containers and natural lighting can start for under twenty dollars. Professional setups with LED lighting and commercial trays may cost several hundred dollars.

Basic equipment includes containers, growing medium, seeds, and basic tools. Recycled takeout containers cost nothing, while commercial seed trays range from fifteen to fifty dollars depending on size and quantity. Growing medium costs vary from five dollars for basic potting soil to twenty dollars for premium organic mixes.

Ongoing expenses include seeds, growing medium replacement, utilities, and occasional equipment replacement. Seed costs typically represent the largest recurring expense, ranging from two to ten dollars per variety. Quality seeds produce better yields, making them worthwhile investments.

Utility costs for artificial lighting add to operational expenses. LED systems consume less electricity than fluorescent alternatives while providing better light quality. A typical LED setup for small-scale production adds five to fifteen dollars monthly to electricity bills.

Price comparisons with store-bought microgreens reveal significant savings potential. Retail prices for organic microgreens range from four to twelve dollars per ounce in most markets. Homegrown production costs typically fall between fifty cents and two dollars per ounce including all inputs.

Break-even analysis shows that most home growers recover initial investments within three to six months of regular production. Volume considerations affect the timeline, with larger operations reaching profitability faster due to economies of scale.

Long-term savings become substantial for families that consume microgreens regularly. Annual savings can reach several hundred dollars for households that incorporate microgreens into daily meals. Quality improvements over store-bought alternatives provide additional value.

Commercial potential exists for growers who want to offset costs through small-scale sales. Local markets, restaurants, and neighbors often pay premium prices for fresh, locally grown microgreens. Regulatory considerations vary by location and scale of operation.

Investment recovery calculations should include both direct savings and improved nutrition benefits. Health benefits from increased vegetable consumption may reduce healthcare costs over time, though these benefits are difficult to quantify precisely.

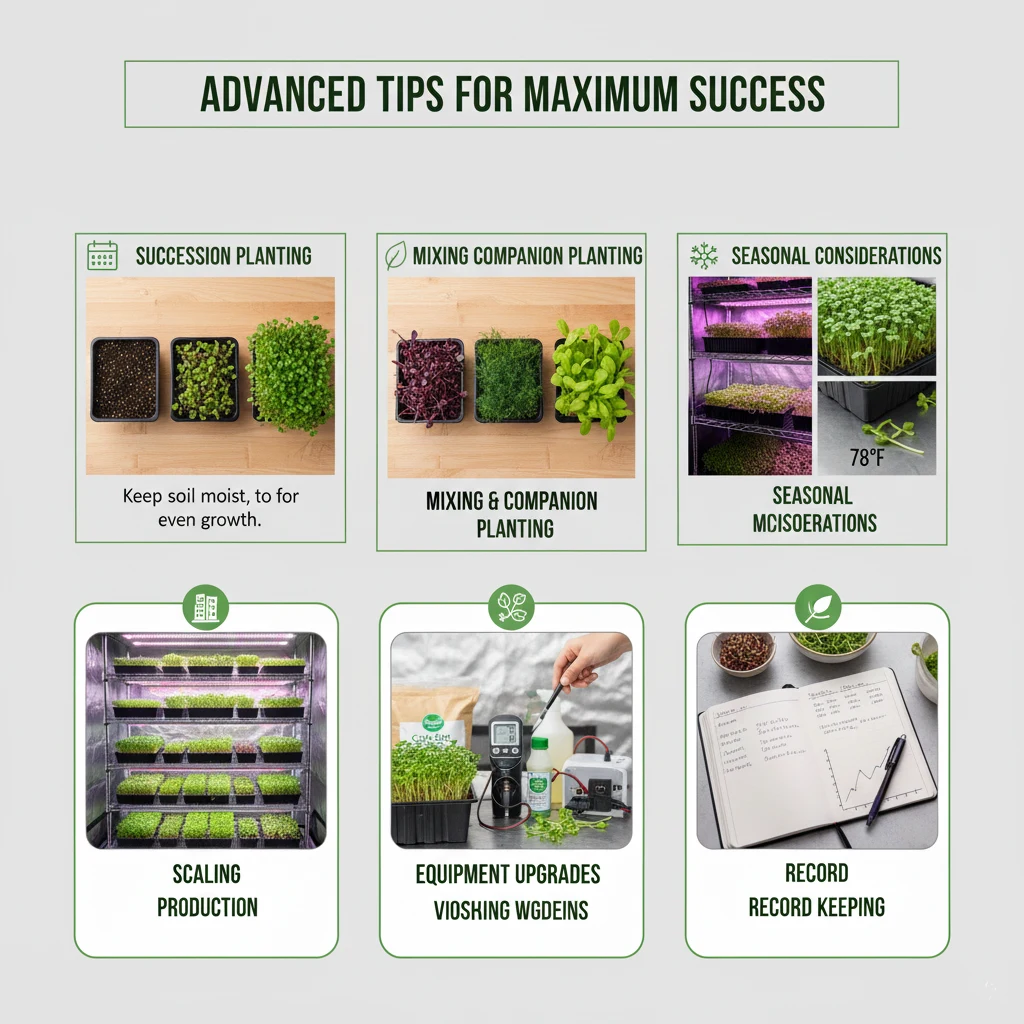

Advanced Tips for Maximum Success

Succession planting ensures continuous harvests of fresh microgreens. Staggered sowings every few days provide steady supplies without overwhelming abundance. Plan planting schedules based on consumption patterns and storage capabilities.

Continuous harvest techniques maximize productivity from limited space. Start new trays as older ones approach harvest maturity. Planning tools like simple calendars help track planting and harvest dates for multiple varieties.

Mixing varieties in single trays creates interesting flavor combinations and visual appeal. Compatible varieties with similar growing requirements work best for mixed plantings. Consider growth rates and harvest timing when planning combinations.

Companion planting principles apply to microgreen production. Complementary flavors like mild and spicy varieties can balance each other in mixed plantings. Growth habits should be similar to ensure even development across the tray.

Seasonal considerations affect both growing conditions and variety selection. Winter growing may require supplemental heating or lighting in cold climates. Summer production might need cooling strategies to maintain optimal temperatures.

Quality improvement techniques focus on optimizing environmental conditions and harvesting practices. Fine-tuning lighting, temperature, and moisture levels produces superior microgreens. Experimentation with different varieties and growing methods leads to improved results.

Scaling production requires systematic approaches to maintain quality while increasing volume. Space utilization becomes critical as operations expand. Vertical growing systems maximize production in limited areas.

Equipment upgrades can improve efficiency and results as operations grow. Professional tools like pH meters and growing media help optimize conditions. Automated systems for watering and lighting reduce labor requirements for larger operations.

Record keeping becomes important for tracking successes and identifying improvement opportunities. Growth logs documenting varieties, conditions, and results help refine techniques over time. Cost tracking ensures profitability for commercial operations.

Frequently Asked Questions About Growing Microgreens

Soil alternatives work well for microgreen production. Hydroponic methods using growing mats or coconut coir produce clean microgreens without soil particles. Soilless growing reduces contamination risks and simplifies harvesting and cleaning processes.

Growing medium options include specialized hydroponic mats, coconut coir, vermiculite, and perlite mixtures. Each medium offers different advantages regarding water retention, drainage, and cost. Beginner growers often find soil-based methods more forgiving.

Sunlight requirements vary by variety and growing goals. Direct sunlight isn’t necessary for most microgreens, but adequate light intensity is crucial. South-facing windows provide sufficient natural light in most climates, while north-facing locations typically require supplemental lighting.

How many times can microgreens be harvested? Space requirements are minimal compared to traditional gardening. Countertop growing works well for small quantities, while dedicated growing areas support larger production. A square foot of growing space can produce substantial quantities of microgreens.

Vertical systems maximize production in limited space. Shelving units with multiple levels can multiply growing capacity. Light requirements must be met for each level to ensure proper development across all trays.

Safety considerations for raw consumption include proper sanitation and handling. Homegrown microgreens are generally safer than commercial alternatives because growers control all production factors. Organic practices eliminate pesticide concerns common with conventional produce.

Regrowth potential varies by variety and harvesting method. Most microgreens are single-harvest crops that require replanting after cutting. Some varieties like pea shoots may produce secondary growth, but quality typically declines with subsequent harvests.

Nutrient testing isn’t necessary for home production, but understanding nutritional content helps plan balanced diets. Research data shows microgreens consistently provide higher nutrient densities than mature vegetables across most vitamins and minerals.

Organic certification for home production isn’t practical, but organic practices are easily implemented. Use organic seeds, growing media, and avoid synthetic chemicals throughout the growing process.

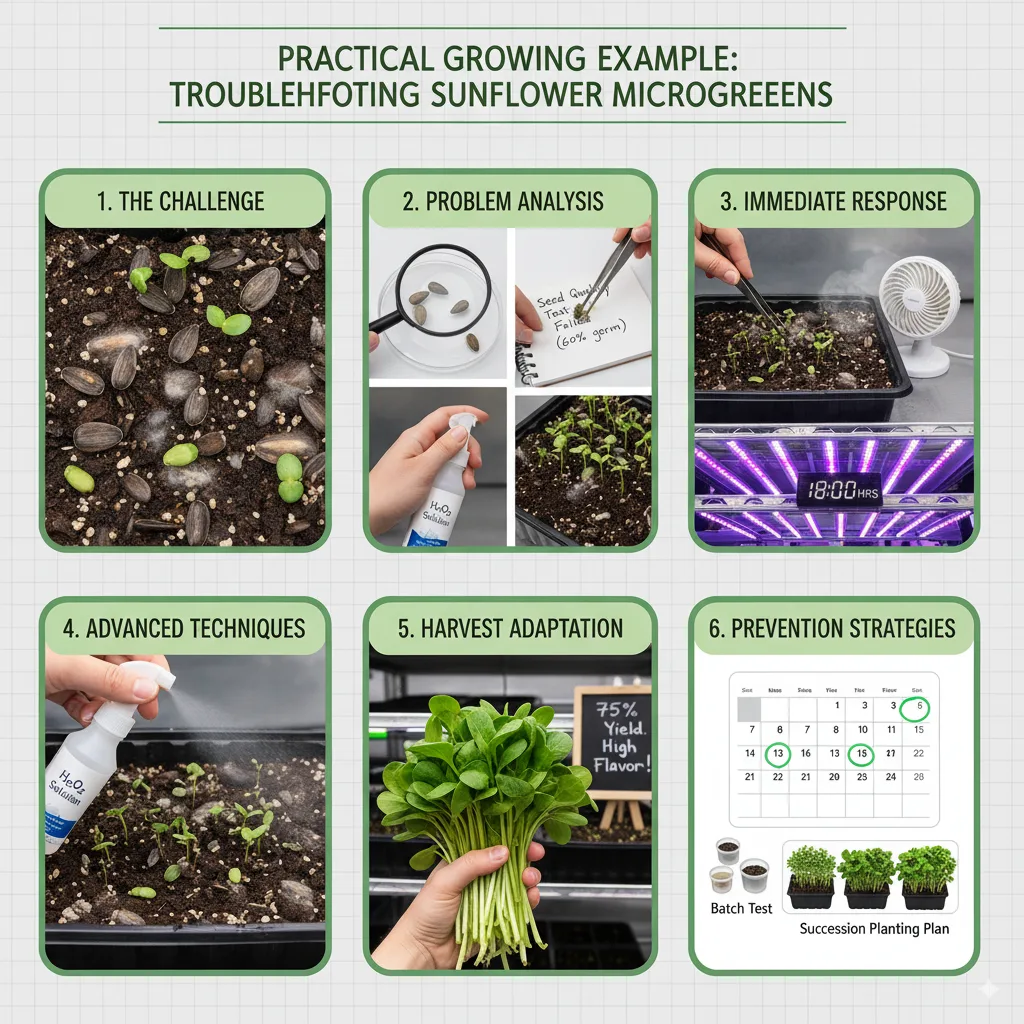

Practical Growing Example: Troubleshooting Sunflower Microgreens

Let’s examine a detailed troubleshooting scenario with sunflower microgreens that demonstrates advanced problem-solving techniques. This real-world example shows how experienced growers handle challenges that might discourage beginners.

The Challenge – Week 1: Mark, an intermediate grower, planted sunflower microgreens using his standard technique but noticed uneven germination after three days. Only sixty percent of his hulled sunflower seeds sprouted, while his usual success rate exceeded ninety percent. The ungerminated seeds showed signs of mold development around day four.

Problem Analysis: Mark investigated potential causes systematically. First, he checked seed quality by testing a small sample in a separate container with fresh growing medium. The test batch showed similar poor germination, indicating a seed quality issue rather than environmental problems.

Immediate Response – Days 4-5: Rather than discarding the entire tray, Mark carefully removed moldy seeds and ungerminated areas using sterilized tweezers. He improved air circulation by adding a small fan and reduced watering frequency. The healthy seedlings continued developing normally while the cleaned areas prevented mold spread.

Advanced Techniques – Days 6-8: Mark applied hydrogen peroxide treatment (one part 3% hydrogen peroxide to ten parts water) as a light mist to remaining problem areas. This organic fungicide approach controlled mold without harming healthy seedlings. He also adjusted his lighting schedule to provide eighteen hours of LED light instead of his usual sixteen hours, compensating for the reduced plant density.

Harvest Adaptation – Days 12-14: Despite the initial setbacks, Mark achieved seventy-five percent of his normal harvest weight. The sunflower microgreens that survived showed exceptional quality with thick stems and vibrant green cotyledons. The extended light exposure produced more concentrated flavors than his previous harvests.

Lessons Learned: This experience taught Mark several valuable lessons. Seed sourcing matters significantly, especially for larger seeds like sunflowers that require hulling. Batch testing new seed lots prevents large-scale failures. Adaptive management during problems can salvage partial harvests rather than complete losses.

Prevention Strategies: Mark now tests small batches of seeds before large plantings, sources seeds from multiple suppliers to avoid single-source failures, and maintains backup plantings staggered by a few days. These risk management approaches ensure continuous harvests even when individual trays encounter problems.

This practical example illustrates how troubleshooting skills develop through experience and systematic problem-solving approaches. Advanced growers learn to adapt techniques based on conditions rather than following rigid procedures.

Commercial Microgreens Production at Home

Commercial potential for home-based microgreen operations extends beyond personal consumption to legitimate income generation. Market demand for locally grown, fresh microgreens continues expanding as restaurants and health-conscious consumers seek premium produce.

Business planning requires understanding local regulations, target markets, and production capabilities. Cottage food laws vary by state and locality, affecting legal requirements for home-based food production. Research local regulations thoroughly before selling any products.

Target markets for home producers include local restaurants, farmers’ markets, health food stores, and direct-to-consumer sales. Restaurant clients often pay premium prices for consistent, high-quality microgreens delivered fresh. Subscription models provide steady income streams for established producers.

Production scaling must balance quality with quantity. Commercial yields require larger growing areas, more sophisticated equipment, and systematic production schedules. Quality control becomes critical when serving paying customers who expect consistent results.

Pricing strategies should account for all production costs plus reasonable profit margins. Premium positioning works well for superior quality products, while competitive pricing may be necessary in saturated markets. Value-added products like microgreen mixes can command higher prices.

Equipment investments for commercial production include professional growing trays, commercial LED lighting systems, temperature control equipment, and packaging materials. Initial investments can range from five hundred to several thousand dollars depending on production scale.

Record keeping becomes essential for commercial operations. Track production costs, yields, customer preferences, and profitability metrics. Business licenses, insurance, and tax considerations require professional advice for legal compliance.

Marketing approaches for microgreens emphasize freshness, local production, and nutritional benefits. Social media marketing, farmers’ market presence, and direct restaurant relationships build customer bases effectively. Educational content about microgreen benefits helps justify premium pricing.

Seasonal planning accounts for varying demand throughout the year. Holiday seasons often bring increased restaurant demand, while summer months may see reduced interest in indoor growing. Diversification with multiple varieties and growing schedules smooths income fluctuations.

Sustainable Microgreens Growing Practices

Sustainable practices in microgreen production reduce environmental impact while maintaining productivity. Resource conservation, waste reduction, and renewable inputs create environmentally responsible growing systems.

Water conservation techniques include drip irrigation systems, water recycling, and moisture monitoring to prevent overwatering. Rainwater collection can supplement tap water supplies, while greywater systems may work for non-food applications like cleaning.

Energy efficiency focuses on LED lighting systems, proper insulation, and natural lighting utilization. Solar panels can offset electricity consumption for larger operations, while passive solar design reduces heating and cooling requirements.

Waste reduction strategies include composting spent growing medium, reusing containers, and minimizing packaging. Vermicomposting systems can process organic waste into valuable soil amendments. Seed hull management through composting prevents waste stream problems.

Organic certification may be worthwhile for commercial operations targeting premium markets. Certified organic inputs and practices command higher prices while supporting environmental sustainability. Documentation requirements for certification can be substantial but provide market advantages.

Local sourcing of supplies reduces transportation impacts and supports regional economies. Regional seed suppliers, local growing medium sources, and nearby equipment vendors minimize supply chain environmental costs.

Integrated pest management using beneficial insects, companion planting, and natural deterrents reduces chemical inputs. Preventive measures like sanitation and environmental controls work better than reactive treatments.

Carbon footprint reduction through efficient production, local sales, and minimal processing creates competitive advantages in environmentally conscious markets. Life cycle assessment of production practices identifies improvement opportunities.

Education and outreach about sustainable growing practices helps build community support and customer loyalty. Demonstration gardens, workshops, and social media content promote sustainable approaches while marketing products.

Building Your Microgreens Community

Community building around microgreens creates support networks, knowledge sharing, and market opportunities. Local growing groups, online forums, and educational initiatives foster connections among growers and consumers.

Knowledge sharing through growing logs, technique demonstrations, and troubleshooting discussions helps all community members improve results. Mentor relationships between experienced and beginning growers accelerate learning curves.

Seed swaps and variety trials introduce growers to new varieties while reducing costs. Group purchases of equipment and supplies provide volume discounts. Collaborative problem-solving addresses common challenges more effectively than individual efforts.

Educational outreach to schools, community centers, and health organizations promotes microgreens awareness and consumption. Workshop offerings create income opportunities while building customer bases. Demonstration gardens showcase growing techniques and variety options.

Social media engagement through growing photos, recipe sharing, and technique videos builds online communities. Hashtag strategies connect local growers and create visibility for microgreens benefits. Content calendars maintain consistent community engagement.

Local market development through farmers’ markets, community events, and restaurant partnerships creates demand for locally grown microgreens. Collaborative marketing efforts benefit all community producers.

Research participation in university extension programs, citizen science projects, and variety trials contributes to microgreens knowledge while providing access to new varieties and techniques.

Policy advocacy for cottage food laws, urban agriculture support, and local food systems creates better environments for home and small-scale commercial production.

Conclusion: Mastering Microgreens for Life

Advanced microgreens techniques transform simple home gardening into sophisticated food production systems. The skills developed through systematic practice create capabilities that extend far beyond basic nutrition supplementation.

Problem-solving abilities gained through microgreens challenges apply to broader gardening situations and food security planning. Understanding plant biology, environmental controls, and quality management creates transferable expertise valued in many contexts.

Commercial opportunities provide pathways to income generation while supporting community health and local food systems. The low barrier to entry makes microgreens accessible to people seeking entrepreneurial opportunities in agriculture.

Sustainable practices developed through microgreens production promote environmental stewardship and resource conservation. These approaches model responsible growing methods that benefit both producers and communities.

Community connections fostered through microgreens activities create social networks that extend beyond gardening. Knowledge sharing, mutual support, and collaborative marketing strengthen local resilience and food security.

Nutritional benefits from consistent microgreens consumption support long-term health outcomes while providing culinary variety. The concentrated nutrition available from minimal space makes microgreens valuable for urban food security.

Technical skills mastered through advanced microgreens production prepare growers for larger agricultural projects and professional opportunities. Systems thinking, quality control, and production planning translate to many agricultural and business contexts.

Innovation opportunities in microgreens production continue expanding as technology advances and market demand grows. Early adopters of new techniques and varieties often achieve competitive advantages in developing markets.

The mastery journey in microgreens growing provides lifelong learning opportunities, practical skills, and meaningful connections to food production. Professional-level results are achievable through systematic practice and continuous improvement.

Take your microgreens growing to the next level by implementing these advanced techniques systematically. Sustainable success comes through patient practice, careful observation, and continuous learning from both successes and challenges.

<< Previous : https://thetrendvaultblog.com/how-to-start-growing-microgreens-at-home/

About Priya Harini B

Priya Harini B is an urban gardening specialist who combines peer-reviewed agricultural research with hands-on testing. Every method recommended on this site has been personally validated in real growing conditions. Currently experimenting with vertical systems and container optimization in Madanapalle.

📧 Email | 📬 Subscribe | 💬 Ask in comments

Looking forward to reading more from you.